Copper, Code, and Control: The New Language of Smart Motors

Motors aren’t just hardware anymore—they’re IoT endpoints. Here’s how copper, code, and control systems fuse into a digital dialect that cuts energy cost, boosts uptime, and turn machines into data assets. (All names/data changed to respect NDAs.)

A Quiet Revolution in Motion

Step inside Nexen Drives Pvt. Ltd., a mid-sized plant near Pune, and you’ll notice something subtle — the shift from noise to nuance. Motors that once ran on raw power now run on intelligence. Every vibration, voltage fluctuation, and thermal drift is part of a digital dialogue.

This is not just electrification. It’s cognition — powered by copper, code, and control.

Smart motors are no longer just electromechanical devices. They are IoT endpoints — intelligent, communicative, and self-optimizing.

Copper: The Foundation Gets Smarter

Copper remains the backbone of motion, but the way we use it has changed.

Advanced electromagnetic design software now predicts performance before a single winding is made. 3D digital twins simulate losses, hotspots, and harmonics, helping engineers reimagine geometry down to the last turn.

In modern production lines, AI-assisted winding systems ensure precision that used to depend on manual skill. Each coil is digitally mapped and traceable, feeding performance data back to design teams through the plant’s MES.

Copper, in this new era, is not just conducting current — it’s conducting insight.

Code: The Brain Behind the Torque

Smart motor intelligence lives in code — in the control firmware, the embedded sensors, the edge AI models running diagnostics in real time.

What used to be a fixed control curve is now an adaptive neural model. Firmware reads vibration signatures, torque demands, and environmental variables, constantly recalibrating the motor’s behavior.

When connected to the cloud, that same motor joins a network of thousands — each node learning from the other. Predictive maintenance algorithms flag bearing degradation before human operators notice.

Updates no longer come via toolboxes; they come over the air.

Control: Where Physics Meets Data

Control systems have evolved from switches and drives to intelligent orchestrators.

Today’s VFDs and edge controllers are data hubs — collecting, analyzing, and acting. They blend AI logic with classical control theory to create self-optimizing loops.

Imagine a 5 HP solar irrigation motor in Satara that senses rising fluid head and dynamically adjusts its speed curve — without operator input. The controller learns the seasonal load profile, syncs with weather data, and optimizes energy draw from solar inverters.

That’s not automation. That’s autonomy.

IoT as the Nervous System

Connectivity is no longer optional — it’s the nervous system of modern motor systems.

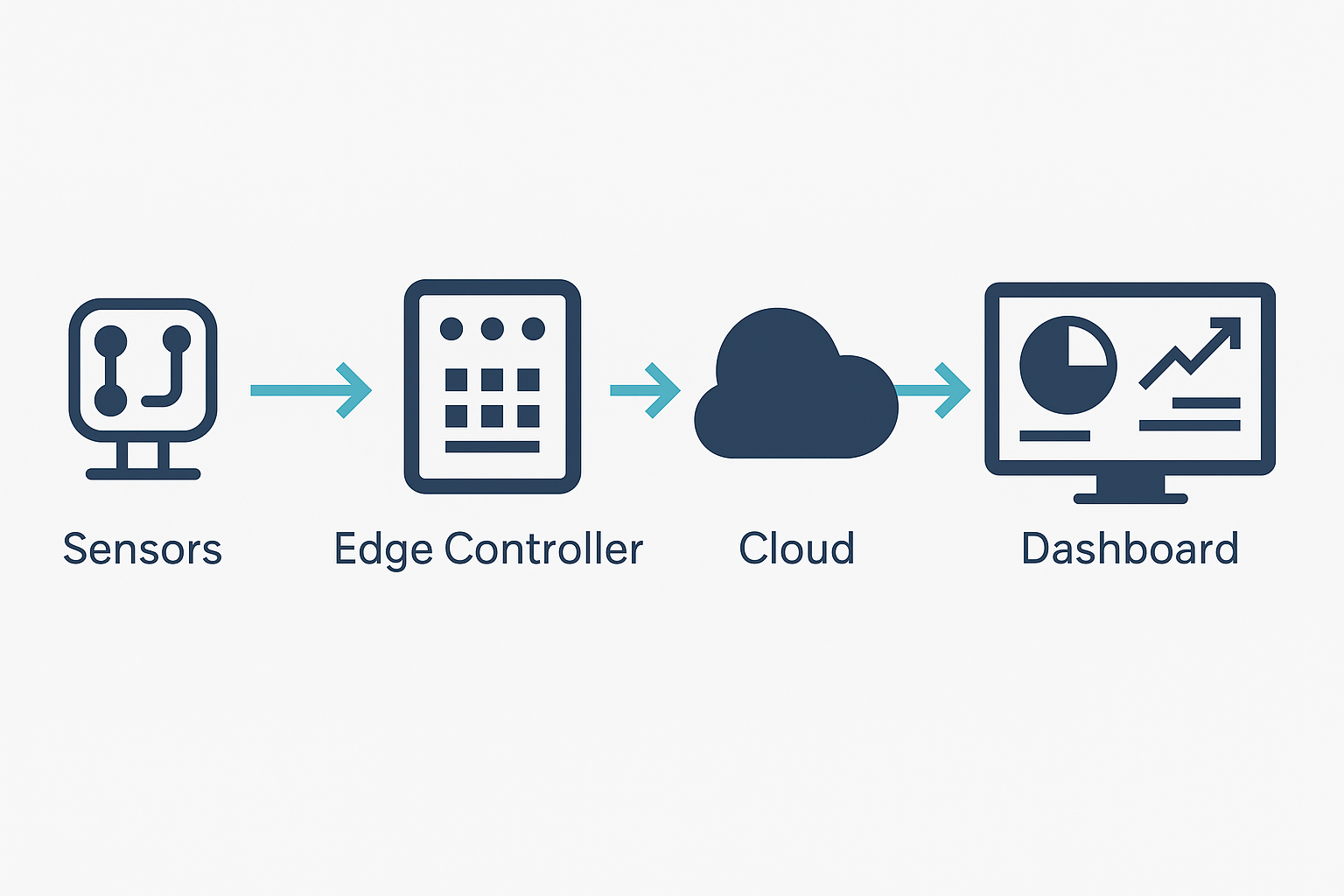

Every motor, drive, and sensor becomes a data node. MQTT protocols, Modbus gateways, and edge analytics platforms link the physical and digital seamlessly.

A central dashboard now shows live KPIs: torque efficiency, winding temperature, harmonic distortion, and downtime probability. Each motor becomes a storyteller — streaming the language of motion to those who know how to listen.

With every connected drive, the factory’s operational intelligence compounds.

The Economics of Intelligence

The payoff isn’t just performance — it’s transformation.

Smart motor systems can reduce energy costs by up to 30%, improve uptime by 40%, and extend life cycles by 25%. Across industries, those numbers reshape margins and sustainability metrics alike.

For OEMs, this means moving from hardware sales to performance-as-a-service — offering predictive uptime, energy benchmarking, and API-level integration with customer systems.

In other words, motors stop being components and become data assets.

Challenges in the Digital Shift

The convergence of mechanical engineering and digital control isn’t frictionless.

Legacy factories wrestle with protocol fragmentation, cybersecurity concerns, and a skills gap between electrical engineers and embedded programmers.

The winning companies are those building cross-disciplinary fluency — mechatronics engineers who speak Python as easily as they read phase diagrams.

That cultural shift may take longer than the tech rollout itself.

The Future: Fluent Motion

Tomorrow’s factory floor won’t just hum — it’ll communicate. Copper will still anchor the physics of motion. Code will still define intelligence. Control will still translate data into power.

But together, they now speak a common language — a digital dialect of efficiency, adaptability, and insight.

And as this new language spreads across sectors — from electric vehicles to agri-pumps to HVAC systems — it’s redefining what it means to build smarter, cleaner, and more connected machines.

Disclaimer: All names and references have been changed to maintain confidentiality and comply with NDA obligations.